- Blog

- May 23, 2024

AI in the Manufacturing Industry (Real-World Examples)

- Blog

- May 23, 2024

AI in the Manufacturing Industry (Real-World Examples)

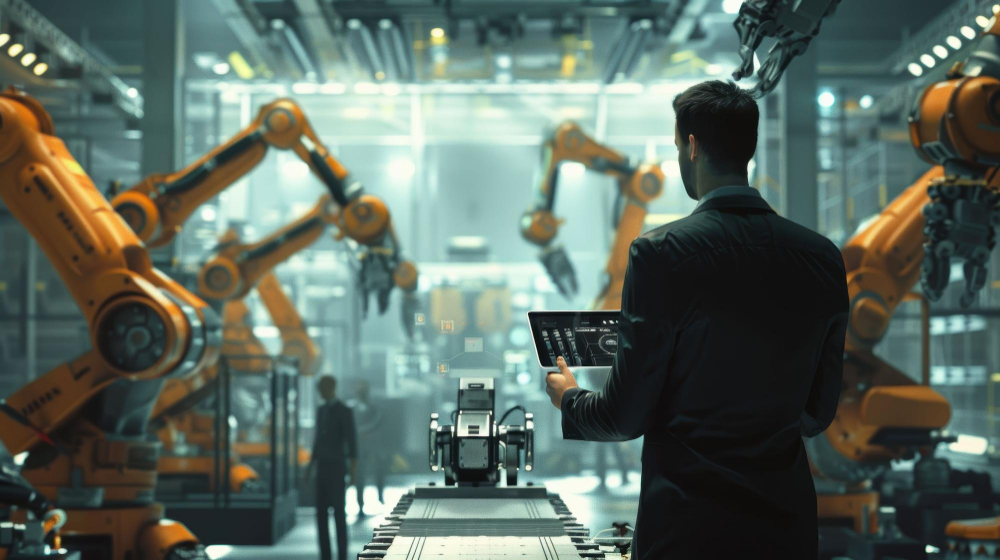

For decades, science fiction has depicted factories overrun by intelligent robots. While reality hasn’t quite reached that point (yet!), Artificial Intelligence (AI) is rapidly transforming the manufacturing landscape. From optimizing production lines to predicting equipment failures, AI transforms how things are made. This blog article delves into how AI is making significant strides in manufacturing, using real-world examples.

The Rise of the Intelligent Factory

Manufacturing has traditionally relied heavily on manual labor and human decision-making. However, AI is injecting intelligence into every stage of the production line. Here are some key areas where AI is making a significant impact:

1. Predictive Maintenance: Foreseeing and Preventing Equipment Failures: Imagine a factory where machines can anticipate their failures before they occur. This is the capability of AI-driven predictive maintenance. By analyzing sensor data from equipment, AI can detect subtle changes that suggest potential issues. This approach allows for pre-emptive maintenance, reducing downtime and boosting production efficiency.

Real-World Example:

- Rolls-Royce, the renowned aerospace and engineering company, utilizes AI for predictive maintenance in its jet engine manufacturing. By analyzing sensor data from test runs, AI can predict potential issues with individual engines, allowing for preventative measures and ensuring the highest safety standards.

- General Electric (GE) utilizes AI to monitor jet engines in airplanes. The system analyzes sensor data to predict potential maintenance needs, ensuring smooth operation and preventing in-flight issues.

2. Quality Control: AI-powered vision systems with deep learning capabilities can inspect products with exceptional accuracy and speed, surpassing human limitations. This ensures consistent product quality and minimizes the risk of defective products reaching consumers.

Real-World Example:

- BMW employs AI for sheet metal inspection, identifying even the most minute flaws that might escape human detection. The system can not only identify traditional defects like cracks but also differentiate harmless blemishes from potential issues, saving time and resources.

3. Production Optimization: AI algorithms can analyze vast amounts of historical data and real-time production metrics to optimize workflows and resource allocation. This allows manufacturers to identify bottlenecks, streamline processes, and maximize production efficiency.

Real-World Example:

- Honeywell leverages AI to optimize production scheduling at their factories, leading to reduced lead times and improved customer satisfaction.

- Siemens, a leading industrial technology company, uses AI to optimize production processes in its factories. By analyzing data on machine performance, material usage, and production times, AI helps identify areas for improvement, leading to significant efficiency gains.

4. Collaborative Robot (Cobot): In the past, robots were often isolated in caged areas to ensure safety. However, the advent of collaborative robots, or cobots, is transforming this dynamic. Cobots are engineered to operate safely alongside human workers, taking on repetitive tasks and aiding with heavy lifting. With AI, cobots can adapt to changing environments and workflows, enhancing efficiency and productivity while maintaining a safe workplace.

Real-World Example:

- Ford employs cobots on their assembly lines. These robots perform tasks like welding and material handling, freeing up human workers to focus on more complex activities.

Beyond Efficiency: The Broader Impact of AI

The benefits of AI in manufacturing extend far beyond increased efficiency. Here’s what AI brings to the table:

- Enhanced Safety: By automating dangerous tasks and predicting equipment failures, AI creates a safer work environment for human employees.

- Improved Sustainability: AI can optimize energy consumption and resource utilization within factories, leading to a more sustainable manufacturing process.

- Product Innovation: AI can analyze customer data and market trends to inform product development and create innovative products that cater to evolving consumer needs.

The Future of AI in Manufacturing

The integration of AI in manufacturing is still in its early stages, but the growth potential is immense. As AI technology continues to evolve, we can expect even more transformative applications, such as:

- Self-Optimizing Factories: Imagine factories that can autonomously adjust production schedules, resource allocation, and even equipment settings based on real-time data and AI analysis.

- Personalized Mass Production: AI could enable the customization of mass-produced goods at scale, allowing manufacturers to cater to individual customer preferences without sacrificing efficiency.

- Hyper-Connected Supply Chains: Real-time data sharing and AI-powered logistics management could revolutionize supply chain efficiency.

Final Takeaway

AI is designed to enhance the role of human workers in manufacturing, not replace them. By automating repetitive tasks and providing crucial data insights, AI enables workers to focus on their strengths such as creativity, problem-solving, and strategic decision-making. This partnership between humans and machines is key to driving a new wave of productivity, innovation, and growth in the manufacturing industry.