- Blog

- January 27, 2022

Blockchain Technology in Manufacturing Industry

- Blog

- January 27, 2022

Blockchain Technology in Manufacturing Industry

Statista has estimated that revenues from blockchain technology will reach 39 billion USD in size by 2025. Empowered with superior qualities of immutability, traceability, transparency, and tight security controls, the popularity of blockchain technology is growing exponentially within the manufacturing fraternity.

The Foundation of blockchain in the Manufacturing industry

Data is the new oil. It is the most valuable asset on the globe as of today. The foundation of blockchain in the manufacturing industry is to classify the ownership and legitimacy of data while also securing it. Although blockchain technology is still a few years away from being fully unleashed, manufacturers are becoming increasingly aware of its potential in their processes.

Using blockchain technology, manufacturers can enjoy operational improvements, limitless supply chain visibility, comprehensive asset monitoring, and reduce costs.

Here are a few live great examples

- Automobile manufacturing giant BMW embarked on a project named PartChain which leverages blockchain for their logistics operations.

- TESLA introduced blockchain in one of their pilot projects which improved sea waybill information accuracy.

- Unilever uses blockchain technology for its tea business to track their transportation

Envisioning Supply chain 2.0 with the best of blockchain

The effectiveness of the supply chain holds the key essence for successful manufacturing. Blockchain can raise the bar for supply chain effectiveness with comprehensive transparency across the entire process value chain of strategic sourcing, procurement, material authenticity, fraud detection, regulatory compliance, and quality assurance.

Infusing blockchain across your supply chain can help ecosystem participants in recording accurate data regarding date, price, location, quality, certification, and other relevant information. This is a dire need in today’s highly connected manufacturing world.

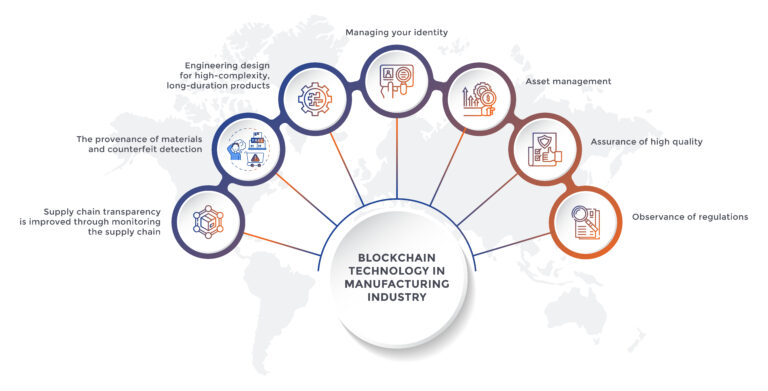

Blockchain in the Manufacturing – The Focus Areas

Manufacturers can take advantage of Blockchain technology in the following focus areas

- Supply chain tracking and tracing via rigorous monitoring

- Material origination and counterfeit detection

- Engineering design for high-complexity, long-duration products

- Asset management, tracking, and traceability

- Assurance of high quality through immutable documentation of quality checks and production process data

Getting Started

As the first step, manufacturing companies need to understand where they can introduce blockchain technology. A detailed assessment of their current processes and approaches is a good start to begin this journey. This assessment exercise has to start by identifying current business gaps, pain points and future goals that could be addressed through blockchain.

Final thoughts

According to forecasts made by Gartner, the business value generated by blockchain technology will reach $176 billion by 2025 and $3.1 trillion by 2030.

Manufacturing has historically been seen as a tradition-bound business. However, factories of the future are poised to look radically different as cutting-edge technologies such as blockchain, AI, and machine learning gain traction. Manufacturers will overcome some of the barriers to full-scale implementation of other next-gen technologies and creative business models as blockchain technology improves. As a result, more efficient industrial operations will emerge, requiring data sharing and collaboration among complex networks of companies and machines. This will become the new standard in the industry.